Basic Info About Ribbon Microphone Transformers

- Author: Artur Fisher

- Published: November 22, 2015

- Updated: January 19, 2024

When it comes to ribbon mic transformers, the correct choice is essential. A poor transformer can ruin the sound of otherwise great microphone. Moreover, even a good transformer must be carefully chosen to match the motor for the best performance. A proper transformer is even more difficult to design than a ribbon motor, as it requires the complex math and understanding of core material properties. The three main parameters of a ribbon mic transformer explained further.

Why Ribbon Mics Need Transformers After All?

First of all, why does a ribbon mic need a transformer? The main disadvantage of a ribbon motor is its ultra-low output level. On the other hand, the main advantage of a transformer is the ability to provide the signal gain without adding the extra noise (as semiconductors would). Therefor, ribbon mics use the transformers in order to raise the signal to a workable level while keeping the reasonable noise floor.

In order to explain the interaction between the ribbon mic transformer and a motor, I have to begin with explaining the three most important parameters of a ribbon mic transformer:

- DC resistance of the primary winding (where the motor is connected)

- Inductance of the primary winding

- Transformation ratio

1. DC Resistances of Windings

The winding of a transformer is a long coiled wire. As any conductor, it has a certain resistance. The general rule of thumb for winding resistance is “less is better”. It might not be very important for many applications, however with ribbon mic transformers the winding resistance is one of the most critical parameters.

The reason is simple. DC resistance causes the signal loss in audio transformers. Whereas, ribbon mic motors produce such tiny signal voltages (in orders of microvolts), that any amount of loss becomes critical. That’s why the DC resistance of the primary (input) winding must be kept to the absolute minimum when designing a ribbon mic transformer.

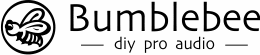

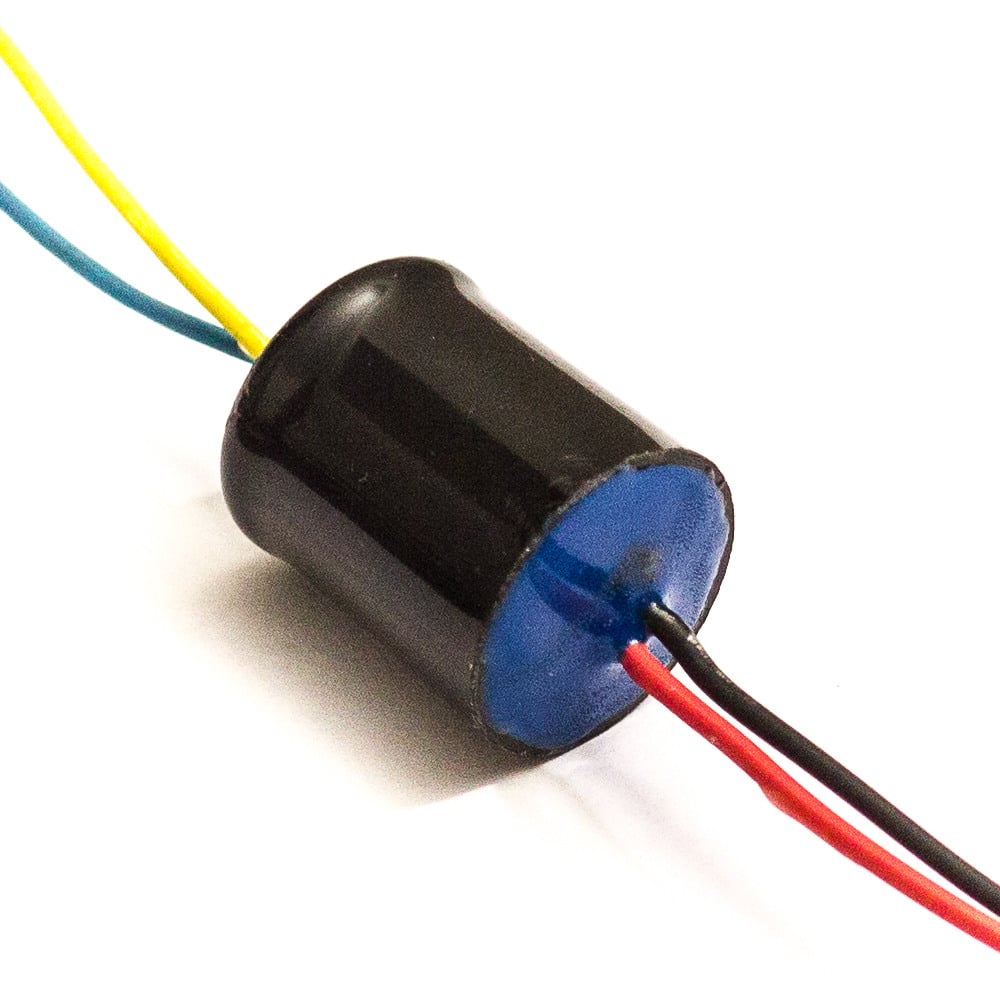

The good practice is to use the thickest wire possible for primary winding. Some manufactures use double wire (shown to the right), as it halves the resistance without increasing the size of a transformer.

2. Inductance of the Primary Winding

The inductance is a little more difficult to explain. In very simple terms, the lowest frequency a ribbon mic transformer can transfer depends on the ratio between the output impedance of a motor and the inductance of primary winding. Assuming that the same motor is used, the transformer with higher primary winding inductance will have the deeper low end. Or vise versa, if the motor has a higher output impedance, you need a higher transformer inductance to maintain the same bass roll-off.

The ribbon mic motor impedance mostly depends on the resistance of the ribbon. While, the resistance depends on the ratio between the cross-section area and the length of a ribbon. It means that thin and narrow ribbons need transformers with higher inductance.

Please note, that with ribbon microphones you don’t always need to go as low as possible with the bass performance. In ribbon microphones a resonant frequency is located in low range, usually around 30 – 50 Hz. Therefore, you may want to reduce the low-end amplitude by using a transformer with a lower primary inductance.

3. Transformation Ratio

This one is quite simple. The transformation ratio is the ratio between the number of turns in primary and secondary windings. The signal voltage multiplies proportionally to the transformation ratio. So, if the transformer has a ratio of 1:35, the signal will be amplified by 35 times. Correspondingly, such ribbon mic transformer will provide around 30 dB of voltage gain. The most widespread ratios among the ribbon mic transformers range from 1:28 to 1:40.

Now, the logical question pops up – if the transformers provide extra gain without adding the noise, why not increase the ratio further? The answer is simple. Transformers increase the output impedance together with the gain. Moreover, while the gain increases proportionally to the ratio, the output impedance increases by the square of the ratio.

It means, that there must be a balance between the signal gain and the reasonable output impedance. For microphones it is 250 – 300 ohms by modern standards. Such impedance corresponds to 1:40 ratio with a typical big ribbon. For thinner and narrower ribbons with higher output impedance the ratio is lower, 1:28 is a typical value. Such ribbon mic transformers also normally have higher primary winding inductance to maintain the even bass response.

Bobbin vs Toroidal Transformers

Transformers come in two construction types – bobbin and toroidal. Both have advantages and disadvantages. There are two big advantages in toroidal design. First, the circumference of a single wire turn is much shorter than with bobbin transformers. It means less wire and thus much lower winding resistance. Second, the toroidal transformers have a great natural EMI immunity and often don’t need screening.

On the other hand, the biggest advantage of bobbin transformers is very low winding capacitance. However, a ribbon motor is a current driver. It produces high current relatively to its ultra-low voltage. Current sources natively perform very good with capacitive loads, so low capacitance does not offer any major improvements in ribbon microphone application.

Also, toroidal transformers require more complicated machinery, as they are quite tricky to make, especially the small ones. It results in another disadvantage – toroidal transformers usually cost more than their bobbin brothers. However, not a lot more nowadays.